Shenyang EMT Piping Technology Co., Ltd

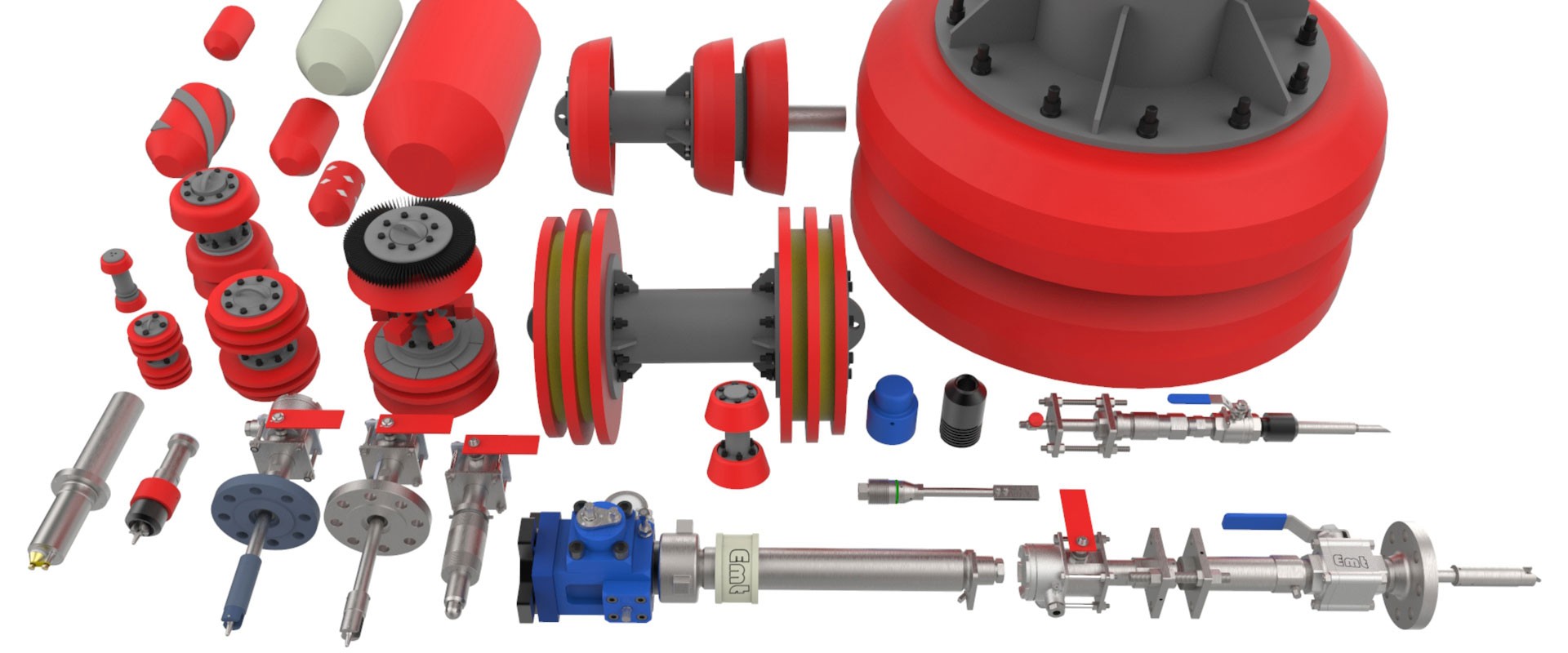

Shenyang EMT Piping Technology Co.,Ltd is formerly known as Shenyang Institute Of Sources Technology Development, which was found in 1993, as one of the first companies to develop pigging products in China. As the company gradually expanded, EMT came into being in 2004. EMT mainly produce pipeline pig, pig signaller, corrosion coupon, chemical injector, insulation joint and quick opening closure, who has now become a scientific research enterprise in collection of research, development, sales and service. Daqing Oilfield and Liaohe Oilfield are our long-term domestic partners. You could enjoy no MOQ and prompt delivery from us because of our advanced management concepts and reliable raw material supplier. Considering for customers, let production transparent are EMT's tenets.

-

This non-intrusive Intrusive Pig Signaller is used to determine whether the pig passes or not during pigging of oil, gas, water and other transmission pipelines.

Details -

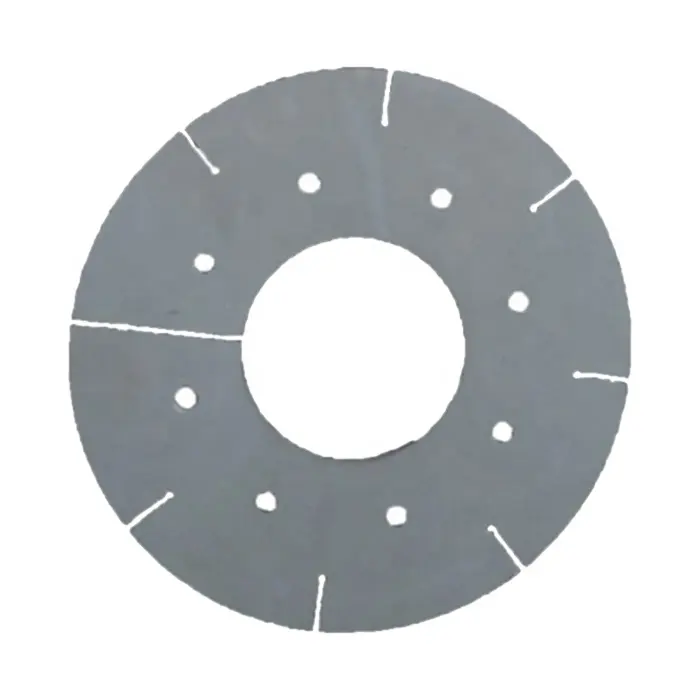

Corrosion coupons play a vital role in detecting and assessing the corrosion condition of pipeline systems. They provide precise and reliable information about the extent of corrosion occurring within the pipelines, aiding in effective maintenance strategies. By accurately displaying the corrosion status, corrosion coupons contribute to proactive pipeline management and facilitate timely interventions to mitigate corrosion-related issues.

Details -

The Uni-directional Scraper Pig is a commonly used pig consisting of four cups and a steel frame. This pig is designed to effectively remove soft dirt and dust from pipelines. Its leather cups serve two important functions. Firstly, they provide excellent sealing performance, ensuring complete separation of liquids or gases at both ends of the pig. This creates a pressure difference that propels the pig forward. Secondly, the leather cups are capable of cleaning debris and dirt from the inner walls of the pipe.

Details -

We take great pride in ensuring the safe and secure packaging of our products, and one of the methods we employ is the use of wooden cases. When it comes to protecting valuable and delicate items during transportation, wooden cases offer exceptional durability and reliability.

Details

-

We are delighted to announce the successful conclusion of our company's staff training program. Over the past few weeks, our dedicated team of professionals has come together to participate in a series of enriching and informative sessions. The training program was meticulously designed to address the evolving needs of our industry and equip our staff with the knowledge and skills necessary to excel in their roles. From interactive workshops to engaging presentations by industry experts, our employees were provided with valuable insights, practical tools, and best practices to enhance their performance.

28-06-2024 -

As one of the most basic methods of corrosion monitoring, corrosion coupon monitoring has the characteristics of simple operation and high data reliability, and can be used as an important basis for equipment and pipeline material selection. At present, there are two main methods of corrosion coupon technology used in Shengli Refinery.

12-06-2024 -

The Polyurethane Coating Foam Pig is a foam pig designed with an inner core made of polyurethane foam and a polyurethane coating on its surface. This unique structure provides portability as a foam pig and offers corrosion resistance properties. As a result, it can be effectively used for pipe cleaning and internal inspection during the initial stages of pipeline construction. Additionally, its excellent sealing capabilities make it suitable for fluid blocking purposes. The foam density of the Polyurethane Coating Foam Pig can be customized according to specific requirements. For pipe drying applications, it is recommended to use low-density foam. However, for pipe cleaning and batching, customers are advised to opt for medium-density or high-density foam. This foam pig is widely popular and commonly utilized, making it a reliable choice when there are no specific demands or preferences.

29-05-2024

With Pressure Removal Tool

Brush Foam Pig

Cup Pipeline Pig

Chemical Injector Quill

Welded Removable Pig Signaller

Corrosion Probe

Bi-di Disc Pig

Criss Cross Foam Pig

Removable Pig Signaller

Flange Pig Signaler

Corrosion Coupon

Quick Opening Closure Vertical

Solid Cast Pig

Solid Cast Cleaning Pig

Cup Pig

Cups Pipeline Pig

Pipeline Pig

Retrieval Tool

Pig Launcher

Spring Steel Brush