Cleaning Bi-Di Disc Pig

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

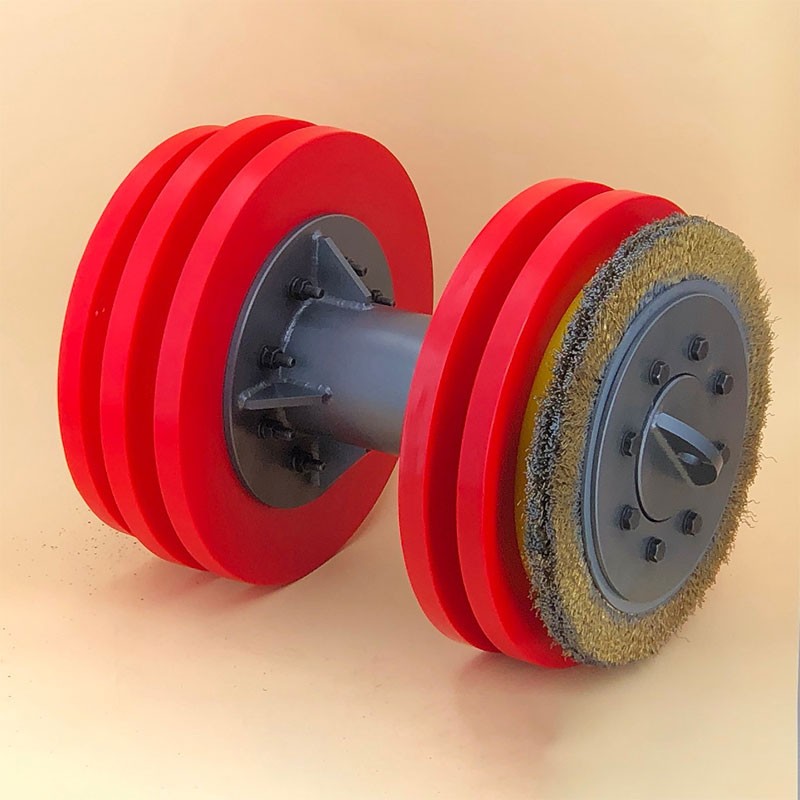

The Cleaning Bi-Di Disc Pig is made of excellent polyurethane raw materials, with high wear resistance, high tear strength, surface opening, double effect of water absorption and cleaning. Cleaning Bi-Di Disc Pigcan solve the task of water absorption and cleaning at the same time. Cleaning Bi-Di Disc Pig has low engineering cost and good cleaning effectadvantage.

Pipe Pig Description

The Cleaning Bi-Di Disc Pig is a highly reliable and efficient tool designed for pipeline cleaning.

With its sturdy steel framework and equipped with 2-4 sealed cups or steel brushes, it offers

exceptional performance. This pig has been extensively used in the renowned Daqing and Liaohe

oil fields, where it has consistently demonstrated stable performance and reliable quality throughout

its long-term usage. Customers have provided positive feedback, commending its effectiveness

and durability. Its versatility allows for various applications, including new pipeline pigging, efficient

drainage, water resistance, and media isolation. With its outstanding cleaning capabilities and

adaptability, the Cleaning Bi-Di Disc Pig proves to be a valuable asset for a wide range of pipeline

operations.

Cleaning Pig Features:

The cleaning pig boasts several notable features, including excellent wearing resistance, strong passing

ability, effective cleaning performance, precise location and tracking capabilities, and a low rate of false

positives. These characteristics ensure its reliability and efficiency in pipeline cleaning operations.

Advantages of the Cleaning Pig:

The cleaning pig offers distinct advantages, such as superior sealing performance and exceptional wear

resistance. Its sealing capabilities are highly reliable, providing an effective barrier against leaks and ensuring

the integrity of the pipeline. Additionally, the pig's high wear resistance enables it to withstand demanding

operating conditions, prolonging its lifespan and reducing maintenance requirements.

TEST REPORT

Report No.TD-20I90117-045N-2 CX99JL03

SUMMARY OF TEST RESULTS | ||||

NO. | TEST PROJECT | UNITS | TEST RESULT | TEST METHOD |

1 | Shore hardness | Shore A | 83 | GB/T531.1-2008 |

2 | DIN abrasion | mm3 | 21 | GB/T53516-1987 |

3 | Akron abrasion | crn3 | 0.0518 | GB/T1689-1998 |

4 | 100%stress at definite elongation | MPa | 3.41 | GB/T528-2009 |

5 | 300%stress at definite elongation | MPa | 5.74 | GB/T528-2009 |

6 | Tensile strength | MPa | 51.2 | GB/T528-2009 |

7 | Elongation at break | % | 1263 | GB/T528-2009 |

8 | Tear strength (right Angle) | kN/m | 77 | GB/T529-2008 |

9 | Resilience rate | % | 34 | GB/T168-2009 |

5. Cleaning pig Specification

Name | Pipe Cleaning Bi-Di Disc Pig |

Material | 1. steel framework main body 2. The disc material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene and etc. 3. The cup material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene and etc. 4. Steel brush or nylon brush |

Feature | 1. good wearing resistance 2. strong passing ability 3. nice cleaning performance 4. accurate location and tracking 5. Low rate of false positives |

Packing way | packed with inner plastic film and outer plywood wooden case. |

Payment | TT/LC |

Advantage | 1. Good sealing performance |

6. Cleaning pig Usage

(1) Cleaning the new-built pipeline.

(2) Remove rust and clean before coating in the pipeline.

(3) Remove rust and clean before repairing the pipeline.

7. Minimum Order Quantity(MOQ):1 Piece.

8. Payment term:T/T or L/C at sight.

The mechanical pig features a reserved control mechanism at the front, allowing for effective control

of its traveling speed within the pipeline. It excels in removing wax deposits, efficiently scraping away hardened wax.

However, its structural complexity limits its passing capacity when encountering deformed pipes or obstacles.

On the other hand, the foam plastic pig is primarily composed of polyurethane foam. It has a streamlined head and

a saucer-shaped tail, with an outer surface wrapped in either a spiral metal belt or an elastic polymer belt. This design

enables the foam plastic pig to provide good propulsion and maneuverability within the pipeline. However, compared

to the mechanical pig, it exhibits lower wear resistance and may not achieve the same level of effectiveness in wax removal

We Shenyang EMT Pigging Technology Co., Ltd. was founded in 2004 has developed to a science and technology development

enterprise that combines science development, product development, production, sales, and service as a whole. The meters,

instruments, and equipment developed have been widely used in petroleum, power, chemical, liquor-making, metallurgy,

mechanical industries. Our institute has professional R&D, sales, site and after service staff with strong strength of R&D,

development, production, and installation.