Disc Pig

The main body of Pipe Pigs is steel framework, equipped with 2-4 sealed cups or steel brush. Our products have been used long-term by the Daqing oil field and the Liaohe oil field with stable performance, reliable quality, has received coherent good comments from the customers.

-

Cleaning Bi-Di Disc Pig

The Cleaning Bi-Di Disc Pig is made of excellent polyurethane raw materials, with high wear resistance, high tear strength, surface opening, double effect of water absorption and cleaning. Cleaning Bi-Di Disc Pigcan solve the task of water absorption and cleaning at the same time. Cleaning Bi-Di Disc Pig has low engineering cost and good cleaning effectadvantage.

Email Details -

Hot

Magnetic Brush Bi-Di Disc Sealing Pig

Rubber material: good sealing performance, maximum 90 degree bending,

Email Details

Suitable for pipeline cleaning in the food hygiene petroleum industry.

Magnetic Brush Bi-Di Disc Sealing Pig is equipped with the position and control of the magnets and can be cleaned and tracked in a closed system.

Magnetic Brush Bi-Di Disc Sealing Pig Modular design

Due to the unified modular system, all components require very few different spare parts, reducing product losses.

Suitable for bending radius 3.0 xD. -

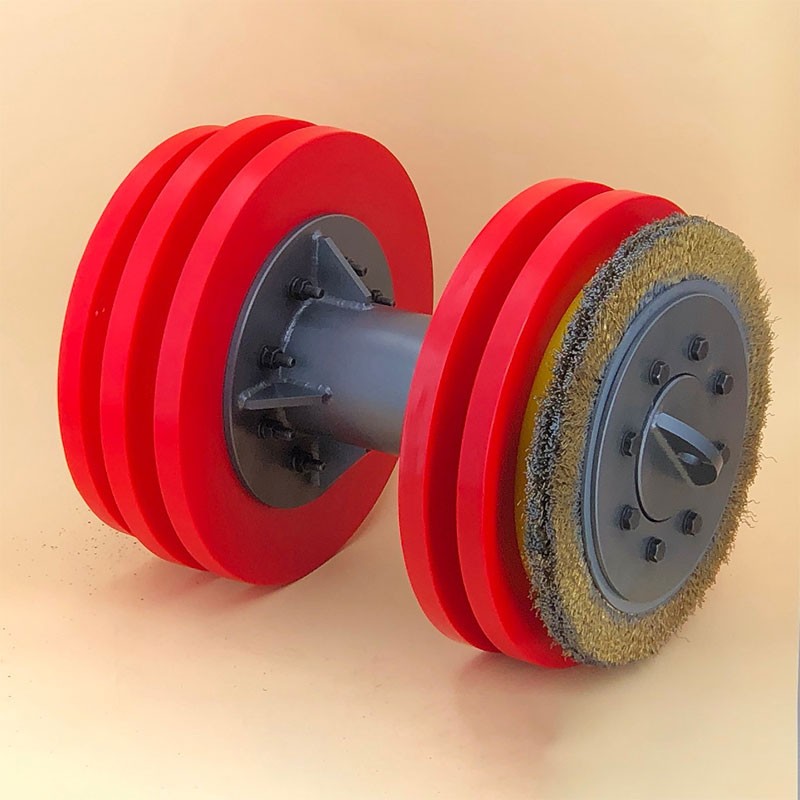

Bi-Di Disc Pig With Brush

The Bi-Di Disc Pig With Brush is made by changing the corresponding disc of the disc pig to a steel brush on the basis of the disc type pig.

Email Details

Bi-Di Disc Pig With Brush has the characteristics of strong passing ability, rust removal and obvious scale effect. Widely used in the decontamination of the inner surface of the pipeline, in addition to soft dirt cleaning and other pigging operations.

It has good sealing performance, good rust and scale effect, especially suitable for derusting operation of medium and long distance pipelines. The elbow that can be passed has a minimum radius of curvature of 4D.