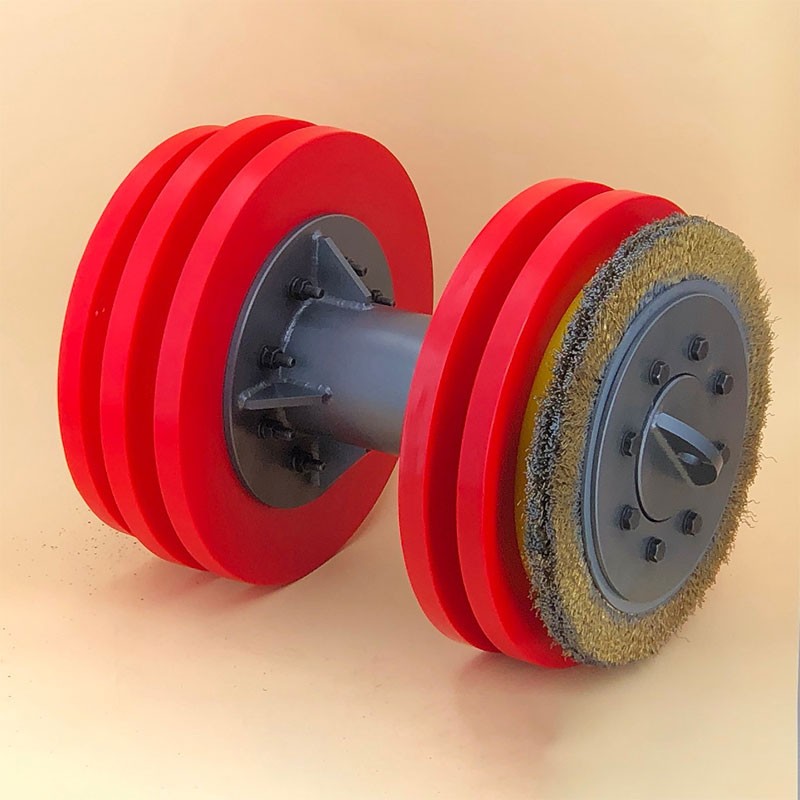

Magnetic Brush Bi-Di Disc Sealing Pig

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

Rubber material: good sealing performance, maximum 90 degree bending,

Suitable for pipeline cleaning in the food hygiene petroleum industry.

Magnetic Brush Bi-Di Disc Sealing Pig is equipped with the position and control of the magnets and can be cleaned and tracked in a closed system.

Magnetic Brush Bi-Di Disc Sealing Pig Modular design

Due to the unified modular system, all components require very few different spare parts, reducing product losses.

Suitable for bending radius 3.0 xD.

Cleaning Pig Description

Introducing the Magnetic Brush Bi-Di Disc Sealing Pig:

This innovative pig features a robust steel framework as its main body, complemented by the inclusion of

2-4 sealed cups or steel brushes. Its exceptional performance and reliable quality have made it a trusted

choice for long-term use in renowned oil fields like Daqing and Liaohe, garnering consistent praise from

satisfied customers.

Material Composition:

The Cleaning Pig's primary structure comprises a durable steel framework, accompanied by the integration

of 6-8 sealed discs or steel brushes. These discs are crafted from a range of high-quality materials, including

Polyurethane, Viton, Neoprene, Nitrile butadiene, among others.

Versatile Applications:

With its steel framework and versatile disc configuration, this pig is designed to excel in a multitude of

applications. It proves highly effective for tasks such as new pipeline pigging, facilitating efficient drainage,

providing water resistance, and effectively isolating different media within the pipeline.

TEST REPORT

Report No.TD-20I90117-045N-2 CX99JL03

SUMMARY OF TEST RESULTS | ||||

NO. | TEST PROJECT | UNITS | TEST RESULT | TEST METHOD |

1 | Shore hardness | Shore A | 83 | GB/T531.1-2008 |

2 | DIN abrasion | mm3 | 21 | GB/T53516-1987 |

3 | Akron abrasion | crn3 | 0.0518 | GB/T1689-1998 |

4 | 100%stress at definite elongation | MPa | 3.41 | GB/T528-2009 |

5 | 300%stress at definite elongation | MPa | 5.74 | GB/T528-2009 |

6 | Tensile strength | MPa | 51.2 | GB/T528-2009 |

7 | Elongation at break | % | 1263 | GB/T528-2009 |

8 | Tear strength (right Angle) | kN/m | 77 | GB/T529-2008 |

9 | Resilience rate | % | 34 | GB/T168-2009 |

5. Cleaning Pig Specification

Name | Magnetic Brush Bi-Di Disc Sealing Pig |

Material | 1. steel framework main body 2. The disc material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene and etc. 3. The cup material used to be Polyurethane, Viton, Neoprene, Nitrile butadiene and etc. 4. Steel brush or nylon brush |

Feature | 1. good wearing resistance 2. strong passing ability 3. nice cleaning performance 4. accurate location and tracking 5. Low rate of false positives |

Packing way | packed with inner plastic film and outer plywood wooden case. |

Payment | TT/LC |

Advantage | 1. Good sealing performance . |

6. Minimum Order Quantity(MOQ):1 Piece .

Key Features of Hot Wax Crude Oil Pipelines:

As the oil flows through the pipeline, its temperature gradually decreases below the wax precipitation point.

This leads to the separation and deposition of paraffin from the crude oil onto the inner walls of the pipe.

Consequently, the flow cross-section is reduced, causing increased friction and decreased pipeline

transportation capacity. Moreover, the presence of wax deposits on the pipe's inner wall raises the thermal

resistance for oil flow and reduces the overall heat transfer coefficient, resulting in higher transportation costs.

The formation of wax deposits on the inner wall of the pipeline presents several challenges for oil transportation.

In the past, measures were taken in Daqing and Shengli Oilfields to control wax build-up by ensuring the oil

delivery temperature remained above 40°C. While this approach helps reduce wax deposition, it also increases

heat loss from the pipeline. To maintain optimal oil transportation capacity at lower economic heating temperatures,

extensive experimental studies have been conducted globally to understand the conditions and mechanisms

underlying wax formation on the inner wall of pipelines.

In this context, various aspects of interior wall management are considered, including the mechanisms of wax

deposition and factors influencing the rate of wax build-up on the inner wall of the pipeline. Additionally, the

impact of temperature drop and increased frictional resistance during the wax accumulation process on the pipe

wall is examined. Furthermore, measures to minimize wax accumulation and techniques for wax removal are

explored as part of ongoing efforts in pipeline management.

Company Information

We Shenyang EMT Pigging Technology Co., Ltd. was founded in 2004 has developed to a science and technology

development enterprise that combines science development, product development, production, sales, and service

as a whole. The meters, instruments, and equipment developed have been widely used in petroleum, power,

chemical, liquor-making, metallurgy, mechanical industries. Our institute has professional R&D, sales, site and after

service staff with strong strength of R&D, development, production, and installation.