Electrical resistance corrosion probe!

Description

Over the years, the technology behind electrical resistance probes has undergone significant advancements, transforming it from its early manual and portable form to an advanced automatic recording system capable of online monitoring. This evolution has made resistance probe monitoring a standard practice in China's refining sector post-2000. The technology is highly regarded for its exceptional sensitivity, rapid response, robust anti-interference capabilities, and broad applicability.

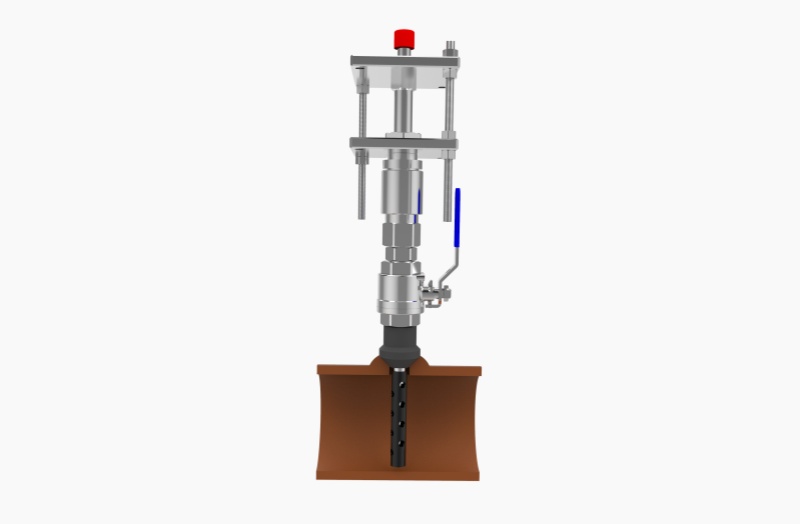

The operational principle of Electrical Resistance Probes developed by EMT is based on a simple yet effective concept. These probes indirectly monitor corrosion by measuring changes in AC signals resulting from metal loss due to corrosion. As shown in Figure 1, corrosion causes a decrease in the cross-sectional area of the probe's measuring element, leading to alterations in the AC signal. By applying an AC signal to the test piece, it becomes possible to determine the extent of thinning and the corresponding corrosion rate. When the material of the measuring element and the erosion state of the medium closely match those of the equipment being examined, the probe's readings accurately represent the corrosion rate of the equipment.

Through technological advancements, EMT has successfully transformed resistance probe technology, making it more efficient, reliable, and suitable for online monitoring. This has significantly contributed to its widespread adoption in the refining sector, where it plays a crucial role in corrosion assessment. The continuous development and improvement of electrical resistance probes ensure their effectiveness in detecting and monitoring corrosion, thereby aiding in the maintenance and longevity of equipment in various industries.