-

High-Performance Hydraulic Corrosion Coupons and Chemical Injection Quills for Oil & Gas Pipelines

In the oil and gas industry, ensuring pipeline integrity and process safety is non-negotiable. One of our recent projects involved the custom manufacturing and delivery of hydraulic corrosion monitoring coupons and chemical injection quills, designed to be installed in high-pressure oil and gas pipeline systems. This case study showcases how our engineering team developed a complete corrosion monitoring and chemical dosing solution to help our client in the petroleum sector maintain operational efficiency and extend pipeline lifespan.

Details -

Precision Chemical Injection Quill Solution for Pipeline Corrosion Control

At Shenyang Emt Piping Technology Co.,ltd., we specialize in delivering high-performance flow control solutions for industrial applications. One of our latest success stories involves the custom design and supply of chemical injection quills for a large-scale pipeline system in the petrochemical sector. This case study demonstrates how our injection quill solution helped our client achieve accurate dosing, corrosion control, and operational efficiency.

Details -

Customized Chemical Injection Quills for Pipeline Integrity Systems!

In this project, we successfully fulfilled a bulk order of customized stainless steel chemical injection quills and valves for a leading oil & gas service company in the Middle East. These components were designed and manufactured specifically for high-pressure pipeline injection systems, where precision, durability, and corrosion resistance are critical.

Details -

Chemical Injector Quill in production!

The EMT Injection Quill Assembly is crafted to precisely administer chemicals into pressurized systems, ensuring thorough mixing and distribution. Its pivotal function includes safeguarding system integrity and optimizing operational efficiency.

Details -

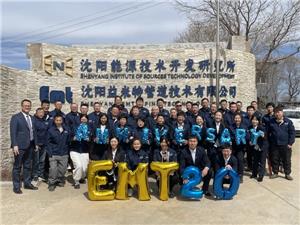

The 20th birthday of EMT!

n the refreshing bloom of spring, we've celebrated the 20th birthday of EMT. Looking back, whether it was the initial team's endeavors, the subsequent application of our products in large-scale international projects, or the continuous breakthroughs in performance we are experiencing now, each step has involved relentless effort and progress.

Details -

Customized Chemical Injector Quill!

The chemical Injection Quills widely work in the world’s oil extraction and processing industry. So the chemical injection pump system is mainly work for inject methanol or glycol into the fluid upstream of the nozzle manifold in oil exploitation. This prevents formation fluid from freezing due to pressure drop, and increases the reliability of the ground test system and the range of pressure drop above and below the nozzle. And it makes the oil (gas) well return to normal work.

Details