Types of Flanges Used in Piping Systems!

Types of Flanges Used in Piping Systems

Flanges are essential components in piping systems, used to connect pipes, valves, pumps, and other equipment. Below are some of the most common types of flanges and their key characteristics:

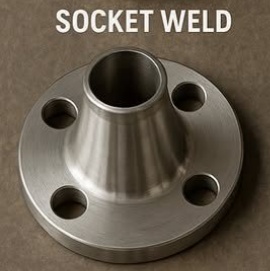

🔧 Socket Weld Flange

Connection: The pipe is inserted into a recessed area of the flange and then welded around the outside.

Use: Suitable for small-diameter, high-pressure pipelines.

Advantage: Ideal for applications where internal welding is difficult, providing a strong and leak-resistant connection.

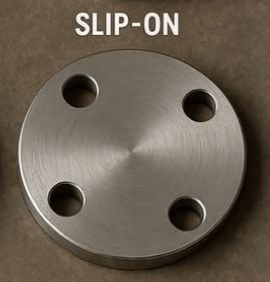

🔧 Slip-On Flange

Connection: The pipe is slid into the flange, and then welded on both the inner and outer sides.

Use: Commonly used in low-pressure and non-critical applications.

Advantage: Easy to align, install, and cost-effective for general piping systems.

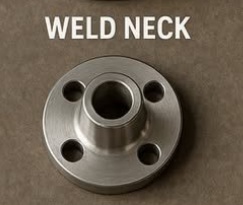

🔧 Weld Neck Flange

Connection: Features a long, tapered hub that is butt-welded to the pipe, ensuring a smooth flow transition and reduced stress concentration.

Use: Preferred in high-pressure, high-temperature, and critical applications.

Advantage: Offers excellent strength and fatigue resistance, making it ideal for severe service conditions.

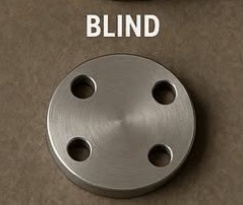

🔧 Blind Flange

Connection: A solid flange with no bore, bolted to the end of a piping system or pressure vessel opening.

Use: Used to seal the end of a pipe or vessel, often for inspection, maintenance, or future expansion.

Advantage: Provides easy access to the system and ensures a tight, secure seal.