Custom Quick Opening Closure Solutions for High-Pressure Pipeline Systems | EMT Case Study!

Overview

At Shenyang EMT Piping Technology Co., Ltd., we specialize in delivering engineered piping components that meet the highest standards of safety, efficiency, and performance. In this case study, we focus on the successful production of Quick Opening Closures (QOCs) for a major international client in the oil and gas industry.

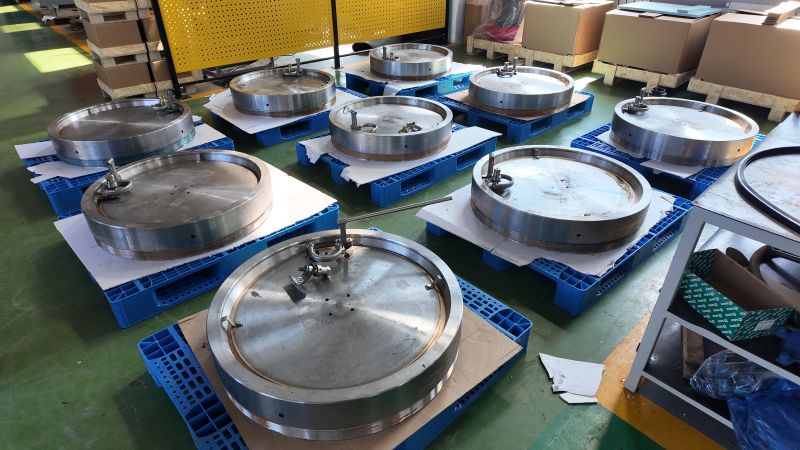

These custom-manufactured quick opening closures, shown in the image above, were designed to provide rapid, safe, and pressure-resistant access to pipeline systems for inspection, cleaning, and maintenance operations. With growing demand for time-saving and secure access mechanisms, quick opening closures have become an essential component in modern pipeline systems.

What is a Quick Opening Closure?

A Quick Opening Closure is a mechanical device installed on pressure vessels or pipelines that allows for fast and easy access to the interior of a pressurized system. Unlike traditional bolted closures, QOCs feature hinged doors, locking mechanisms, and safety interlocks, enabling users to open and close the system in a matter of minutes rather than hours.

They are widely used in industries such as:

Oil & Gas (on pig launchers/receivers)

Petrochemical processing

Water treatment

Power generation

Food and beverage pipelines

Pressure filtration systems

Client Requirements

Our client, a leading oilfield services provider based in the Middle East, required a set of custom quick opening closures for a new pigging system being installed in a remote gas processing facility. Their specifications included:

Material: SS316L for corrosion resistance in offshore conditions

Design Pressure: 1200 PSI

Design Standard: ASME VIII Div.1

Internal Diameter: 850mm

Opening Mechanism: Hinged with hand-wheel lock and safety interlock

Testing: Hydrostatic pressure and leak testing

Certifications: PED and ASME compliance

Our engineering and fabrication teams worked closely with the client’s project engineers to ensure that every detail was optimized for performance, safety, and ease of use.

Manufacturing & Quality Assurance Process

At EMT, we control the full lifecycle of product development, from design to delivery. For this QOC project, the key steps included:

1. Engineering Design

Using industry-leading CAD software, our engineers designed a custom quick opening closure that met the client’s pressure and dimensional requirements, while incorporating safety features such as:

Pressure warning lock

Mechanical interlock to prevent opening under pressure

O-ring groove for leak-proof sealing

2. Material Selection and Machining

We selected marine-grade stainless steel (SS316L) to ensure excellent corrosion resistance. CNC machining was used to achieve high precision within ±0.05 mm tolerances.

3. Assembly and Welding

The closure units were assembled with high-strength hinges, locking rings, and hand-wheel-operated seals. All welding was performed by certified welders according to ASME Section IX procedures.

4. Pressure Testing and Inspection

Each unit underwent hydrostatic pressure testing at 1.5x design pressure and leak detection using helium gas. Dimensional checks, surface finish inspections, and seal integrity tests ensured zero defects.

5. Packaging and Shipment

The closures were individually protected with foam, palletized, and crated for international shipment, complete with technical manuals and certificates.