Corrosion Probes Shipment with Modular Packaging for International Client!

At EMT, we take pride in delivering precision-engineered corrosion monitoring solutions that meet the highest industry standards. In this recent case, we successfully completed a large-volume order of corrosion probes for a long-term international client in the oil and gas sector. This shipment highlights our attention to detail, modular packaging capabilities, and commitment to quality assurance throughout the production and delivery process.

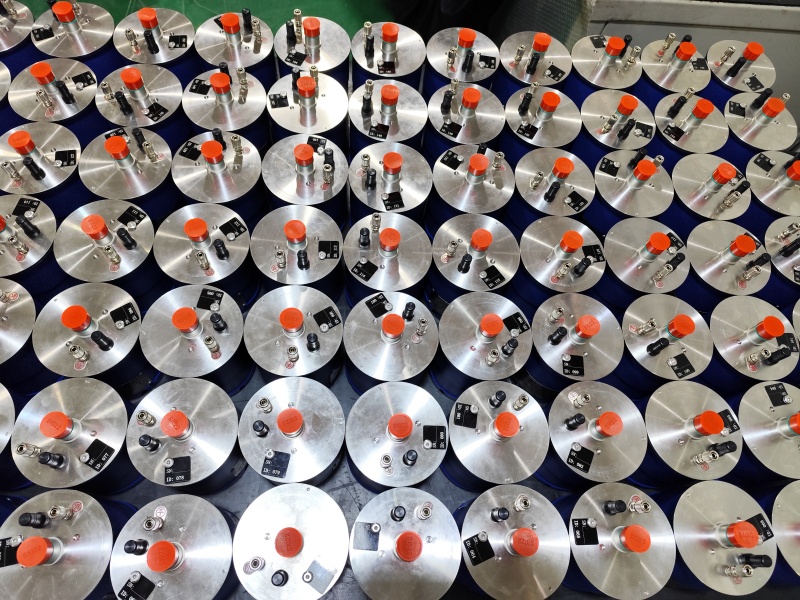

Custom-Engineered Corrosion Probes

The corrosion probes shown in the first image are part of a batch specifically designed for high-pressure pipeline applications. Each unit is manufactured with robust stainless steel components and features precision sensor interfaces. The compact design ensures easy installation via access fittings, while providing accurate and real-time corrosion rate data for pipeline integrity monitoring.

For this project, the client required:

A large quantity of corrosion probes

Strict identification and traceability (each unit is tagged)

Modular packaging for easy field assembly

Separate packing for all accessories

Modular, Protective Packaging

As shown in timage, all components were carefully packaged in a custom-designed wooden crate, with each accessory type (probe rods, cables, connectors, and protective caps) separated and clearly labeled. This modular packaging system:

Simplifies on-site assembly

Protects sensitive components during transit

Minimizes installation errors

Speeds up deployment in the field

The corrosion probes were packed with industrial-grade foam inserts to prevent movement and mechanical stress during shipping. All parts were sealed in anti-static bags and arranged in layers for maximum space efficiency.

Client Benefits

By separating the probe bodies and accessories, our client can now perform quick installations and replacements on-site with minimal downtime. This method also reduces the risk of damage or loss during transport, and aligns with their internal logistics and inspection processes.

Conclusion

This successful delivery reinforces our ability to handle high-volume, customized orders with precision and care. From production to packaging, EMT ensures that every corrosion monitoring product reaches the customer in perfect condition—ready to perform in demanding environments.

We continue to support global clients with reliable, field-proven corrosion monitoring equipment, backed by expert engineering and responsive service.

Interested in our corrosion probes or pipeline integrity solutions?

Contact us today to learn more about our custom manufacturing and international delivery capabilities.